Although the air cleaner in your Massey Ferguson tractor may seem like a minor component, it plays a vital role in ensuring the engine’s longevity and performance. It filters out dust, dirt, and debris from the air before it reaches the engine. Without proper air filtration, contaminants can enter the engine, mix with oil and grease, and act like sandpaper, wearing down engine parts and shortening the engine’s lifespan.

If the air cleaner isn’t cleaned regularly, it becomes clogged, restricting airflow into the engine. This reduces engine strength and increases fuel consumption by as much as 10% to 15%. Proper air cleaner maintenance helps conserve diesel, maintain engine power, and avoid costly repairs.

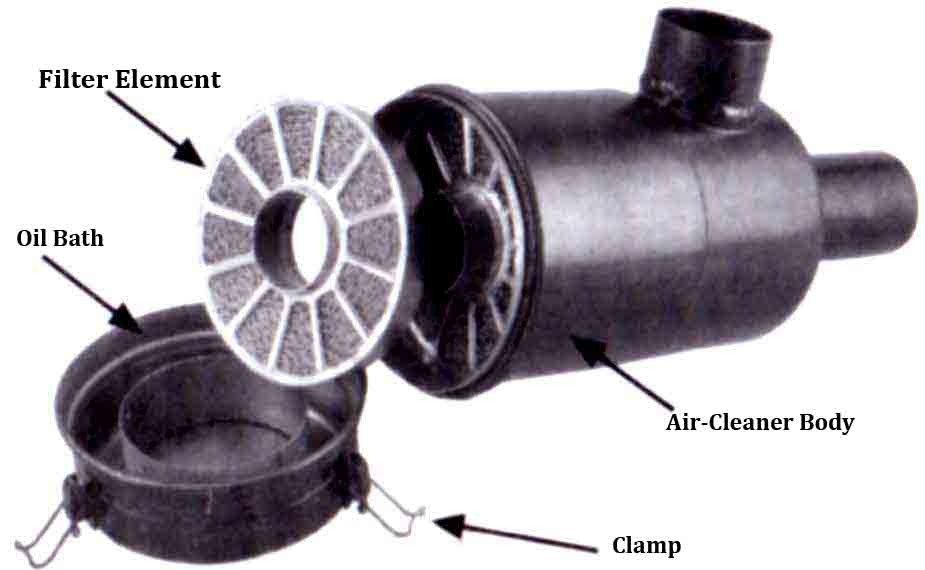

Components of the Air Cleaner:

1.Pre-Air Cleaner:

The air cleaner is covered by a bowl called the Pre-Air Cleaner. Its primary job is to catch large debris like dust, dry grass, and hay. This debris collects in a clear plastic bowl that should be removed and cleaned every day. This step is essential for keeping the air cleaner assembly functioning effectively.

a. Air-Cleaner Body (Permanent Filter): This housing contains the permanent filter and is leading in filtering fine particles from the air.

b. Filter Element: The filter element catches finer dust particles that pass through the pre-cleaner.

c. Oil Bath: The oil bath is filled up to a specific level with engine oil. When air passes through the pre-air cleaner and reaches the oil bath, the air comes into contact with the oil. The oil moves through the filter element and up to the permanent filter, causing it to be covered in oil. This oily filter captures dust particles, allowing only clean air to enter the engine cylinder. Over time, the oil becomes dirty due to this filtration process.

Importance of Regular Maintenance

Daily Cleaning and Checks:

- You should remove the oil bath every day before using the tractor to inspect the oil level and its condition.

- If the oil level is low, fill it up to the required mark with fresh engine oil.

- The oil must be replaced if it has become thick with dust and debris. Empty the oil bath, remove the air cleaner body and filter element, and clean them thoroughly with kerosene.

- After cleaning, refill the oil bath with fresh oil up to the specified level and reassemble it with the air cleaner.

Very Important Maintenance Tips:

- Always check the oil in the oil bath daily. Maintaining the right oil level is crucial for the air cleaner’s efficient functioning.

- Always use engine oil in the air cleaner to ensure proper lubrication and filtration.

- After every 100 hours of tractor operation, clean the oil bath, air-cleaner body, and filter element with kerosene. This thorough cleaning improves engine performance and extends the lifespan of the air cleaner and the engine..